(Português BR) Todo gás natural e biogás sempre saem saturados em água. No entanto, sempre é necessária sua desidratação para atender as especificações comerciais. Existem várias maneiras de desidratar o gás, mas o mais comum é a desidratação com glicol.

Existem quatro glicóis que são usados na remoção do vapor de água. O trietilenoglicol (TEG) é o mais largamente utilizado devido às vantagens em relação aos demais:

- O TEG é mais facilmente regenerado para um maior grau de pureza

- As perdas por vaporização são menores

- Os custos operacionais são mais baixos

Monoetilenoglicol (MEG) não é usado em um desidratador de glicol convencional, mas poderá ser usado na desidratação para diminuir a temperatura de formação de hidratos em unidades de refrigeração.

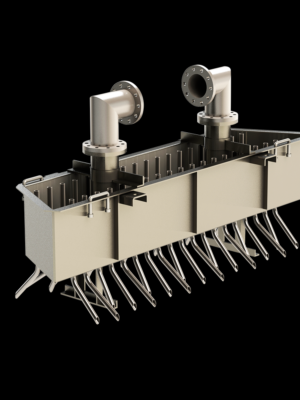

O gás flui através de um separador para remover líquidos condensados ou quaisquer sólidos que possam estar no gás. Alguns absorvedores incorporam o separador em uma seção inferior do recipiente, caso em que o gás então flui para cima através de uma bandeja de chaminé na parte absorvente de glicol do recipiente.

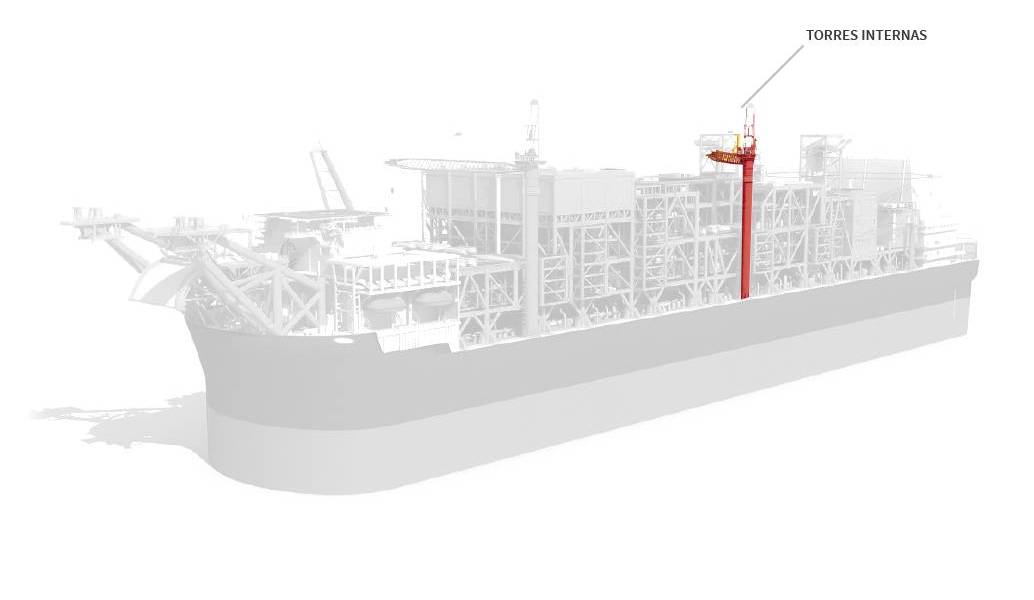

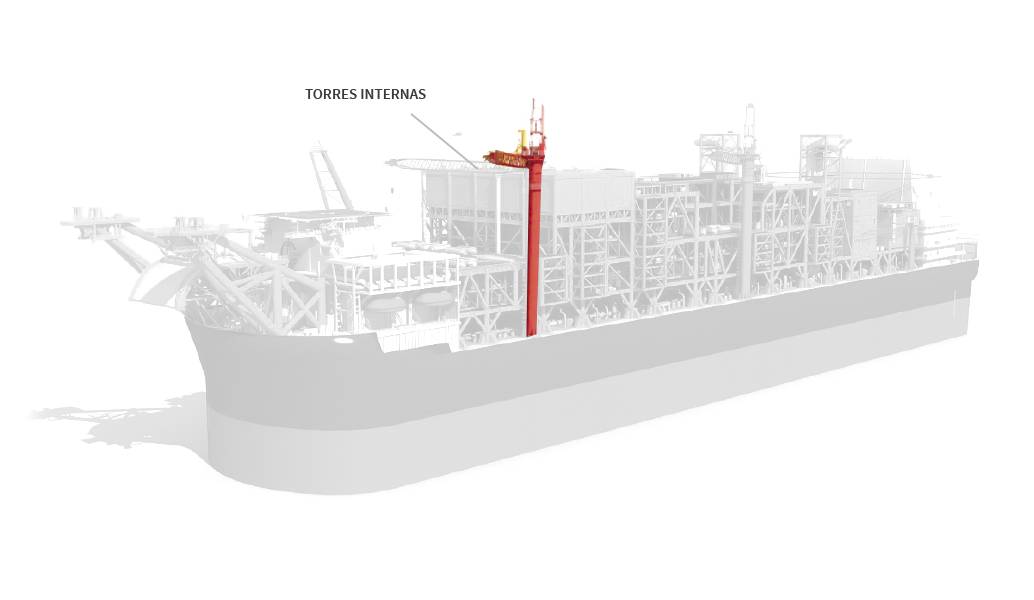

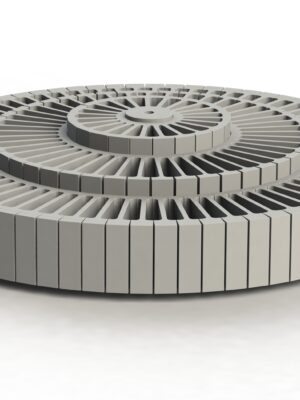

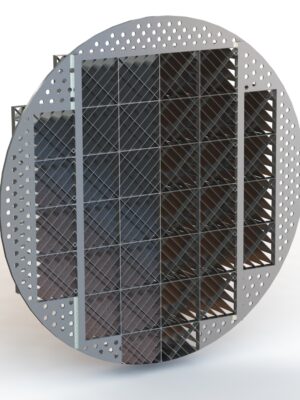

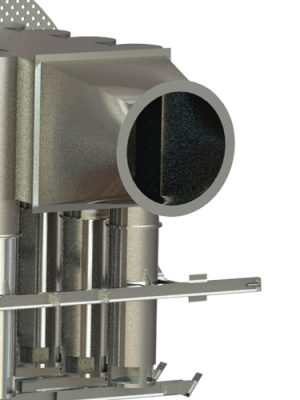

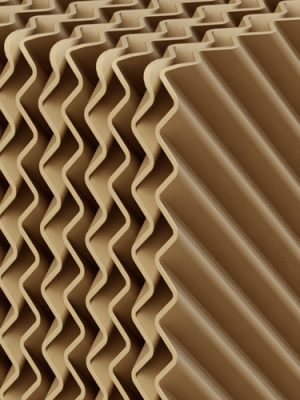

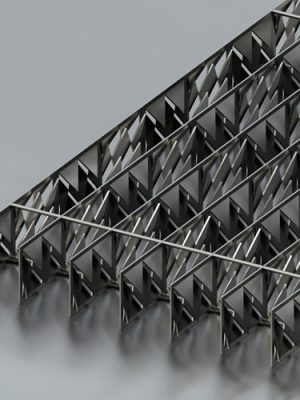

O glicol seco é bombeado para a parte superior do contator, no distribuidor e abaixo do eliminador de névoa. A torre é inundada com glicol, que desce nas seções de recheio ou bandejas. O gás sobe em contracorrente em relação ao glicol. Isso fornece o contato íntimo entre o gás e o glicol, e este é altamente higroscópico e a maior parte do vapor de água do gás é absorvido. O glicol rico, contendo a água absorvida, é retirado do contator próximo ao fundo do vaso, onde passará por um sistema de regeneração em circuito fechado. O gás tratado sai do contator no topo através de um eliminador de névoa e, se corretamente especificado, atende ao teor máximo de água.

Com o aumento de capacidade, poderá haver muitos motivos para não atingir mais a especificação de ponto de orvalho da água.

- Temperatura de entrada de gás maior do que o projeto devido a limitação da capacidade de troca térmica anterior a torre.

- Pressão de entrada de gás menor do que o projeto devido à limitação dos compressores.

- Circulação ou regeneração insuficiente de glicol ou a formação de espuma no absorvedor – problemas bastante comuns mesmo dentro das capacidades atuais.

A Clark Solutions é especialista em sistemas de transferência de massa e pode atuar em trobleshootings e revamps de plantas completas. Consulte-nos.