FiberBed® fiber bed mist eliminators are designed to remove particles of fog, which are small liquid droplets present in a gas stream through beds of glass fibers, polyester, polypropylene or other polymers.

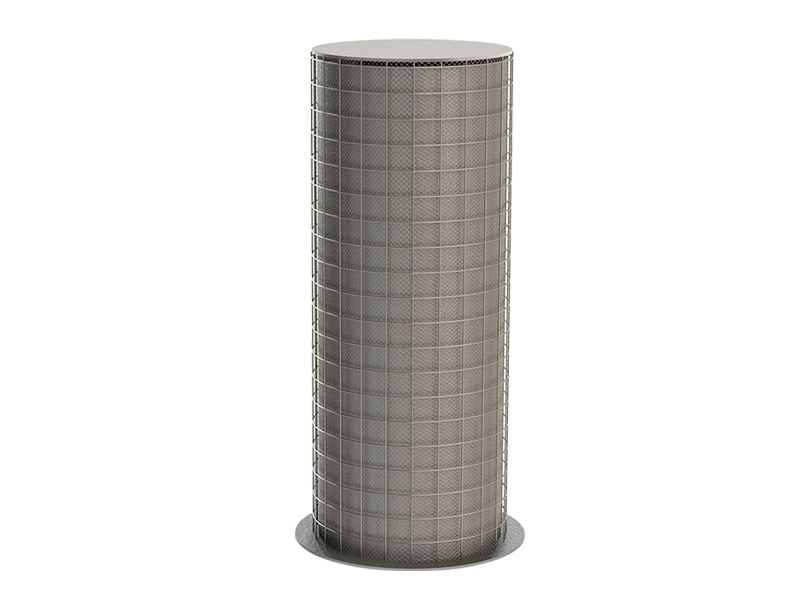

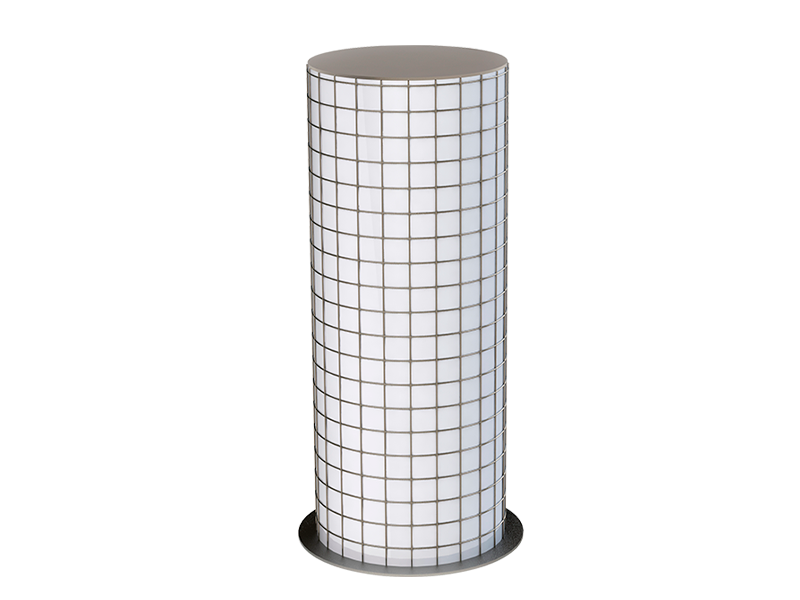

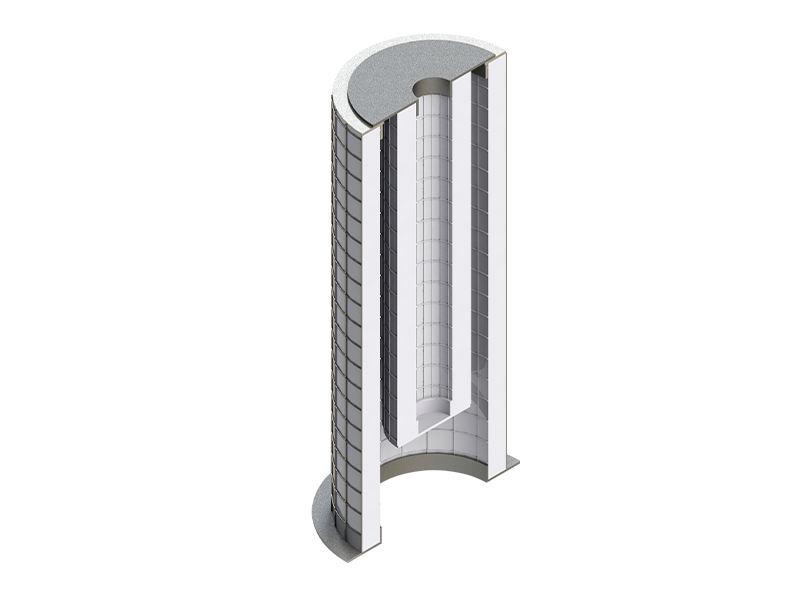

The beds are compacted between coinciding cylindrical screens or parallel plates, in order to randomly distribute the fibers of defined diameters and with the necessary densities to achieve the capture efficiency and loss of design load.

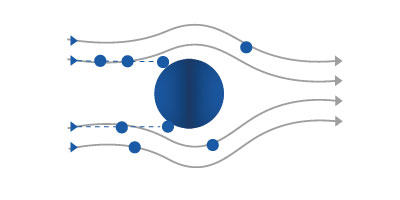

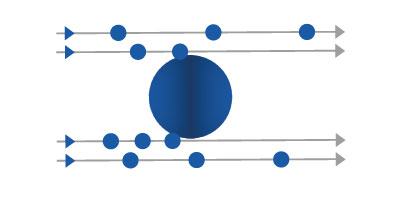

Particles of 3 microns or larger are collected when their moment (kinetic energy) prevents them from following the gas stream lines around a fiber. The moment of the particle causes it to remain on its path reaching the fiber where it is captured.

Since momentum is a function of the particle’s mass and velocity, it follows that large drops will be collected more efficiently than small drops traveling at the same speed. This type of mechanism is extremely dependent on the particle inertia and the viscosity of the gas.

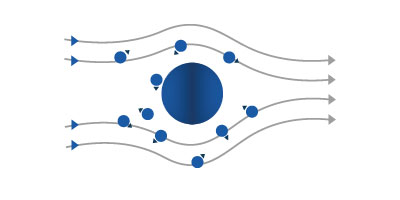

Some particles follow the path of the gas, but due to its diameter they end up “touching” the fibers of the bed, where they are collected. Mechanism little dependent on inertia, particle and gas viscosity.

Sub-chromic particles are collected when their moment (kinetic energy) prevents them from following the gas stream lines around a fiber. The moment of the particle causes it to remain on its path reaching the fiber where it is captured.

Since momentum is a function of the particle’s mass and velocity, it follows that large drops will be collected more efficiently than small drops traveling at the same speed. This type of mechanism is extremely dependent on the particle inertia and the viscosity of the gas.

The FiberBed® Mist Eliminator can be applied to several processes, in the protection of equipment or control of atmospheric emissions. Its main applications are those where there are small particles, less than 3µ, and where they demand high collection efficiencies, normally greater than 99% of the particles.

Developed to collect 75-99% of particles in the 1 to 3 micron range. Inertial impact is used as the main mechanism and capture and, therefore, it is developed to operate at high speeds in the bed (in the range of 1.0 to 3.0 m / s).

Impaction cylinders are typically 650 mm (26 ”) in diameter and 500 mm to 1500 mm in height (20-72”).

Are manufactured using modern techniques and computational control with virtually no human contact. Computerized manufacturing allows continuous monitoring of pressure loss during the manufacturing process. Not all available materials are manufactured in a way that can be computerized.