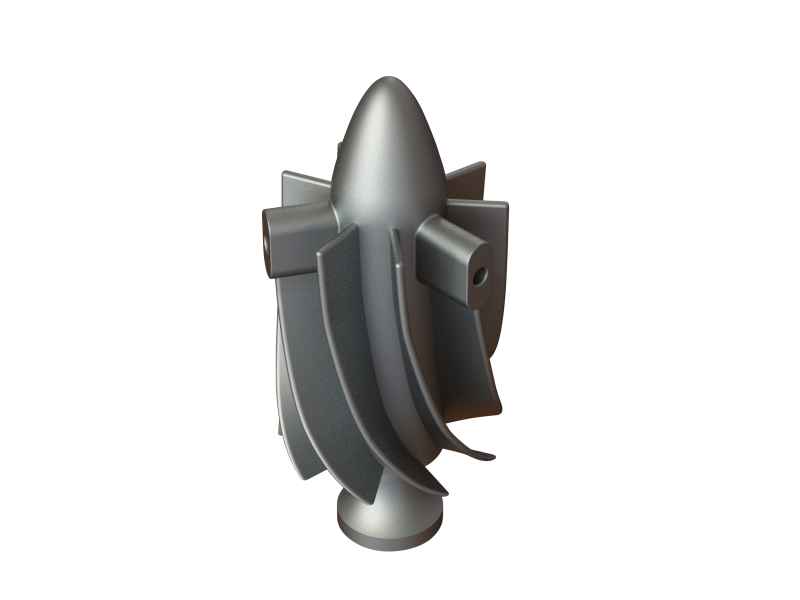

The HeliFlow® mist eliminators of the axial cyclone type are composed of a finned module, which has been calculated and adjusted for maximum efficiency. It is available in all conventional stainless steels and special alloys.

The flow in rotation generates a pressure difference in the radial direction and the particles are forced towards the walls of the tube, where they coalesce and form a liquid film.

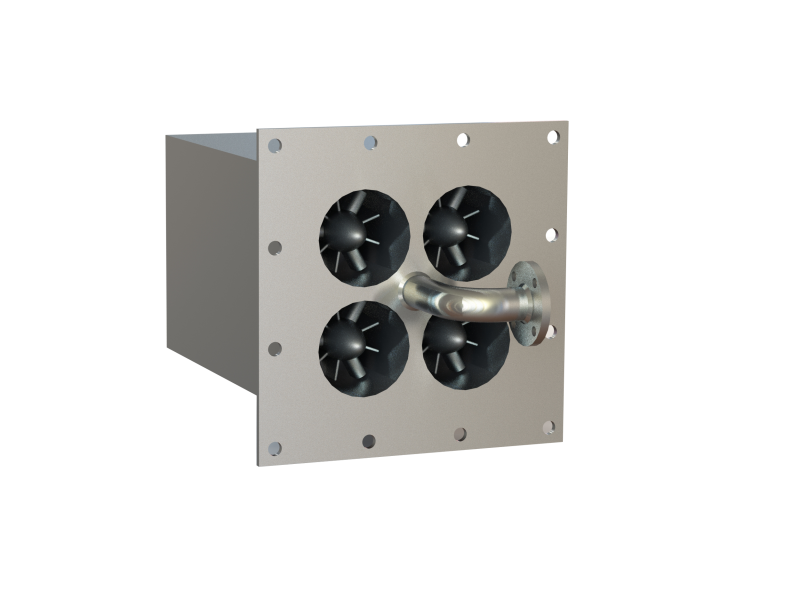

Downstream of the module there are channels for draining liquid in the walls of the tubes, which direct the liquid to the collection boxes. Thus, the liquid is effectively collected and the gas proceeds to the liquid droplet-free process.

In addition to the configuration of the elements to force the separation, the set has interconnections to create pressure differentials in regions of stagnation, which promotes greater efficiency in the collection and drainage of the liquid.

Available on all conventional stainless steels and special alloys. The selection of materials is made for maximum durability, even in highly corrosive media.