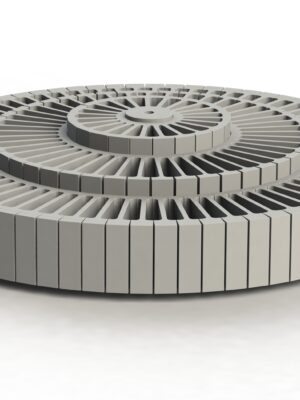

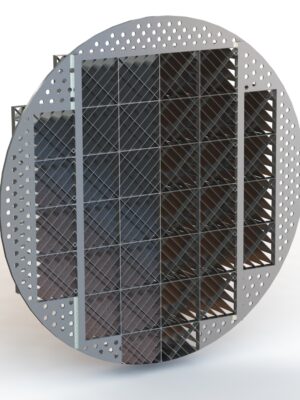

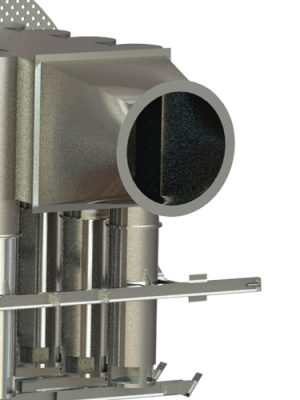

Random Packing | 3-Pack: The random packing 3-Pack® have a “quasi-spherical” geometry, designed to maximize the specific interfacial area in towers and columns for gas absorption or desorption.

Random packing | CMTP: The random packing CMTP® seeks to associate high capacity with an excellent mass transfer efficiency, promoting, also, a low pressure loss through its geometry. CMTP® is manufactured in an extensive range of metal alloys such as 410, 304, 316 and 317.

Random packing | MaxiRing: MaxiRing® random packing increase the efficiency of mass transfer in absorption and desorption processes. Therefore, the greater the contact area between the phases, the better the absorption efficiency.

Random packing | MaxiSaddle: Random packing MaxiSaddles® is widely used in the chemical industry, to promote the transfer of mass between highly corrosive substances, where it is not possible to use plastic and metallic fillings.

Random packing | MaxiSaddle BPC: The random packing MaxiSaddles® BPC (MaxiSaddle Low Load Loss) is the newest generation belonging to the MaxiSaddles ceramic saddle group.

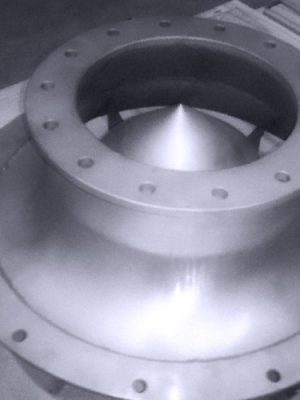

Random Packing | MaxiDur: MaxiDur® random packing have a high density, greater than 2.25 kg / L, making them used as a catalyst support, in order to keep the catalytic beds in position even under extreme flow rates / speeds. gas.

Random packing | β-Ring®: The high performance β-Ring® packing promotes major improvements when compared to conventional random fillings.

Learn more