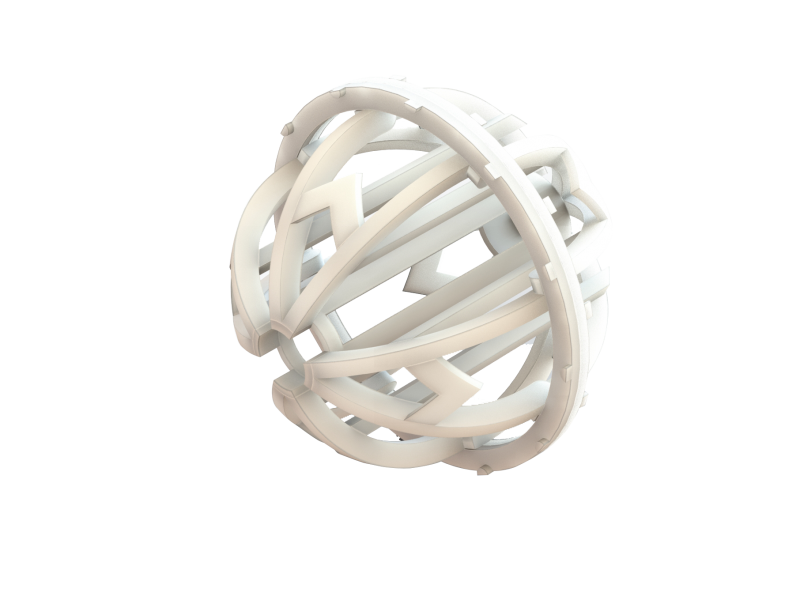

The random packing 3-Pack® present a “quasi-spherical” geometry, designed to maximize the specific interfacial area in towers and columns of gas absorption or desorption.

Its shape offers an excellent surface area and a constant renewal of the liquid film, maximizing the global mass transfer coefficient by 20-30% when compared to 1st and 2nd generation plastic rings (Raschig Rings and Pall Rings). In addition, there is a 20-30% decrease in head loss when compared to conventional fillings.

Since it has practically no straight corners or points where liquids or solids can accumulate, it has an excellent performance in systems such as washing towers and strippers, in addition to good chemical resistance.

Towers packaged with a random 3-Pack® packing, when compared to other fillings, exhibit greater mass transfer efficiency for the same head loss, allowing the towers designed to use the 3-Pack® to have diameters 20 to 30% smaller and / or use lower total volumes of fillings and / or consume less energy than towers designed with less current technologies.

In addition, the 3-Pack® has manufacturing options in several polymers, they are sized and manufactured according to the operational conditions of the project.