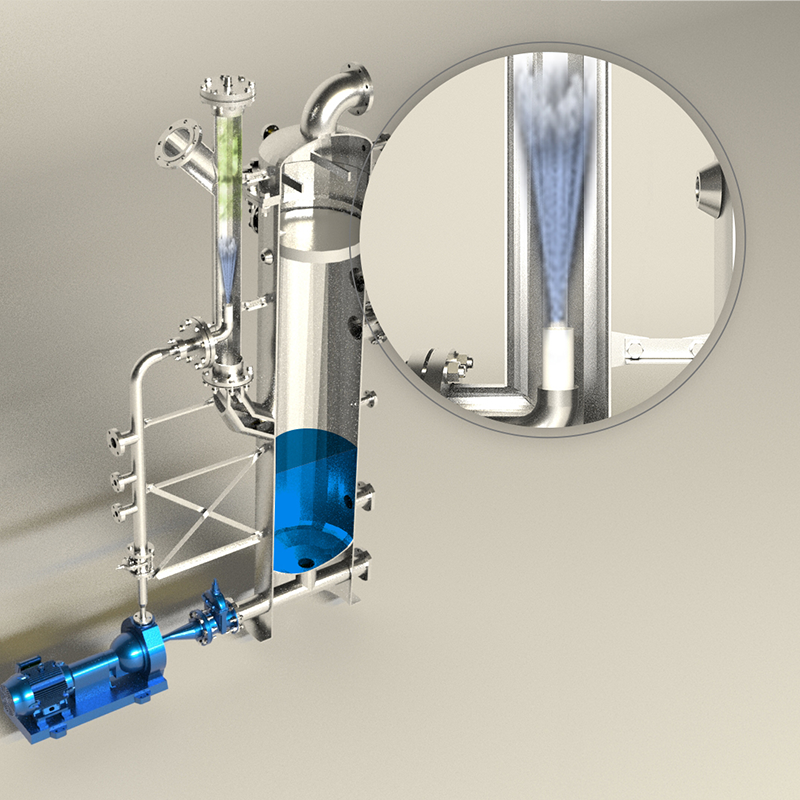

MaxiJet is a gas washing technology capable of cooling hot gases (>1000⁰C), removing particulate solids, and scrubbing gases present in a contaminated gas stream. All of this occurs simultaneously.

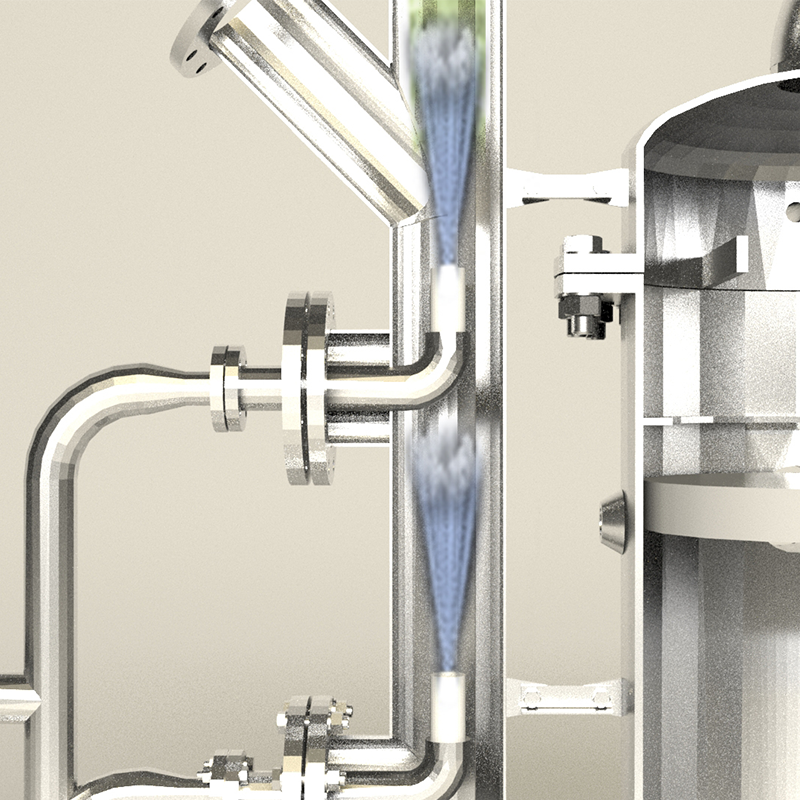

The heart of MaxiJet technology lies in its large-diameter injector nozzle and the adjustment of the gas-to-liquid flow ratios. This combination promotes the formation of a high-turbulence zone where the gas is cooled, solid particles are collected, and gases are absorbed, usually through chemical reactions.

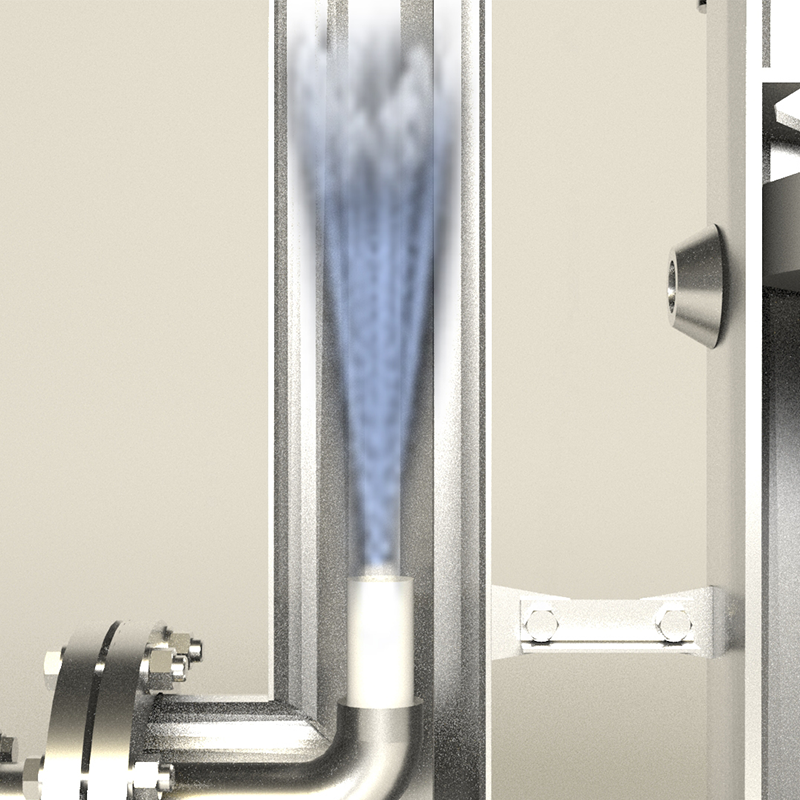

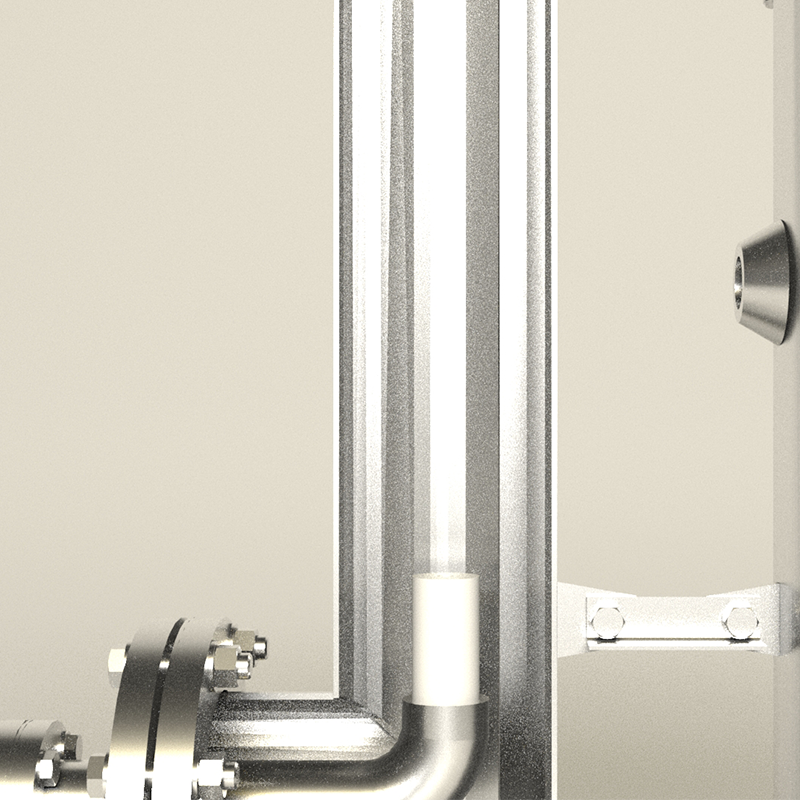

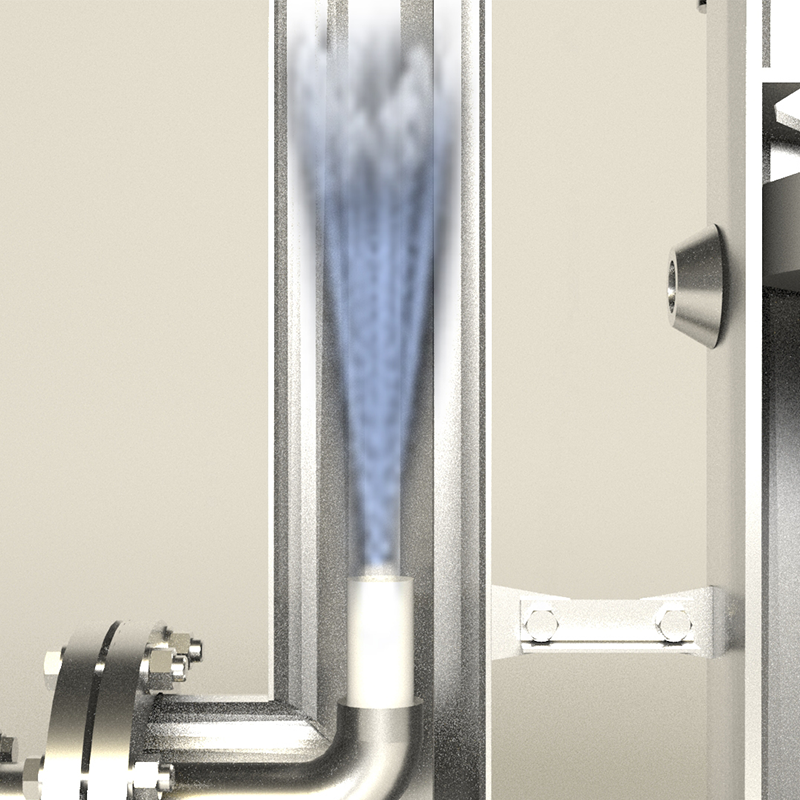

Conventional scrubbers struggle to exceed 2-5% solid concentration, while MaxiJet operates with approximately 20% solids. This is because the ejector nozzle (pictured) is not prone to clogging. As a result, MaxiJet can operate with concentrated solutions and sludges, significantly reducing effluent generation.